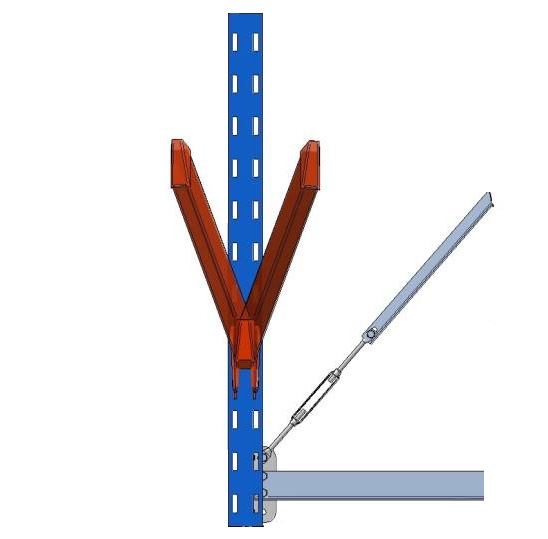

Impact of the cantilever arm in horizontal direction.

heavy duty cantilever racks

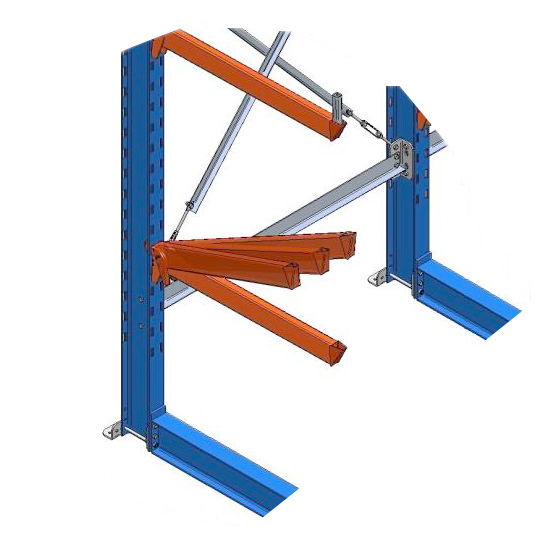

BR heavy cantilever racks are extremely suitable for mechanical loading of heavy goods. Our heavy-duty cantilever racks are supplied as standard with a height of 2½ to 9 meters with 500 mm steps and can be equipped with carrying arms with a length of 600, 800, 1000, 1200, 1500 and 2000 mm with various bearing capacities.

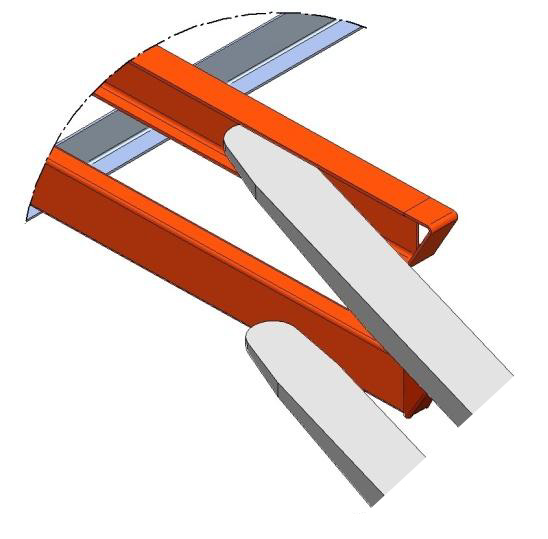

The cantilever racks are ideal for storing long materials. Thanks to the carrying arms that are hooked vertically into the upright, a flexible position is created that can take a beating. The hooking arms are designed to prevent damage to the support arm and the upright. Damage is often caused by an incorrect operation with placement equipment such as a forklift truck. Due to a freedom of movement of the arm, both on the side and up, this is a thing of the past.

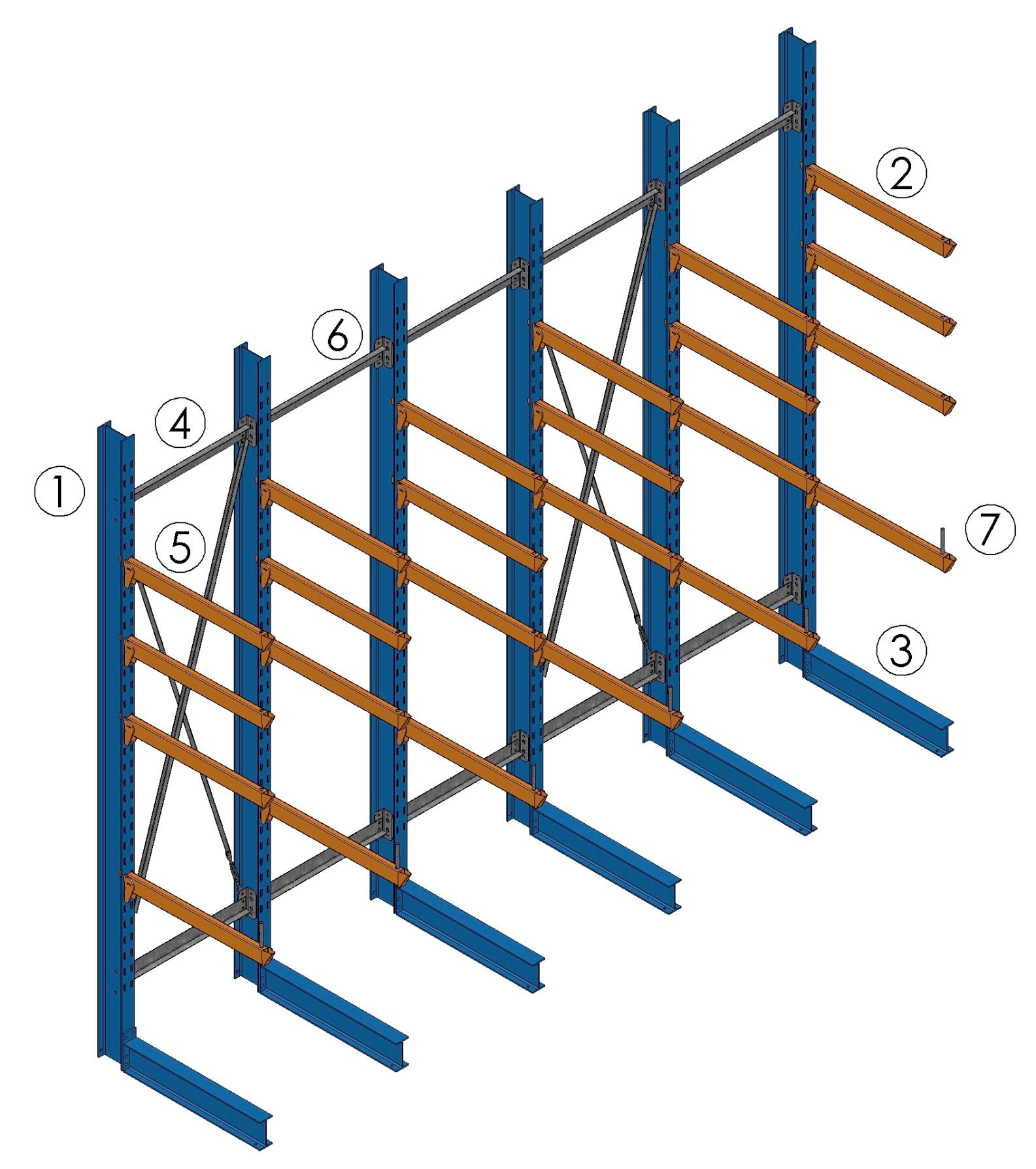

parts

1. Column

2. Cantilever

3. Upright foot

4. Horizontal brace

5. Cross bracing

6. Torque angle

7. Cantilever End stop

2. Cantilever

3. Upright foot

4. Horizontal brace

5. Cross bracing

6. Torque angle

7. Cantilever End stop

Properties

● Columns and feet finished with epoxy coating

● Cantilever arms finished with epoxy powder coating

● Columns and feet RAL 5015, arms RAL 2004

● Bracing sendzimir galvanized

● Galvanized for outdoor storage

● Cantilever arms adjustable per step of 100 mm

● For single-sided and double-sided use

● For crane and forklift truck loading

● Continuous storage via arm bridges

● Cantilever arms finished with epoxy powder coating

● Columns and feet RAL 5015, arms RAL 2004

● Bracing sendzimir galvanized

● Galvanized for outdoor storage

● Cantilever arms adjustable per step of 100 mm

● For single-sided and double-sided use

● For crane and forklift truck loading

● Continuous storage via arm bridges